BRUGG eConnect –

Your Partner for customized cable solutions.

Customized cable solutions

Consulting – Development – Production – Assembly

BRUGG eConnect creates cable solutions when standard products are not sufficient.Cables for temporary construction sites

EPR /PUR cables

Product features

- Produced in Switzerland

- UV and weather resistant, therefore ideal for outdoor applications

- High flexibility

- Comfortable coat

Shielded Cables

All cables are also available in assembled form. If you have any questions, please contact your sales consultant.

Can’t find the cable you’re looking for? Here we create your desired cable for individual needs.

Motor connection cable

All cables are also available in assembled form. If you have any questions, please contact your sales consultant.

Can’t find the cable you’re looking for? Here we create your desired cable for individual needs.

Special and customized cables

You define the requirements, and we deliver the individual, customer-specific solution. As a specialist in sophisticated cable systems, BRUGG eConnect has particular professional skills in the field of Engineered to Order (ETO).

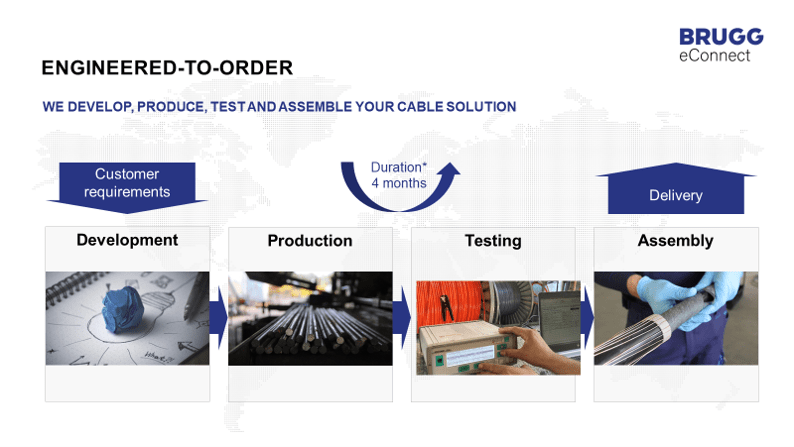

Engineered to Order is a state-of-the-art process in which the individual components are designed and manufactured on the basis of specific customer requirements. Benefit from our comprehensive professional knowledge and extensive experience built up by our specialists. We’re there to provide reliable assistance with challenging connections – from development and design to purchasing, production and assembly on-site.

Our specialists do more than help with advice during the project phase. BRUGG eConnect also provide quite specific services – from drawing up specifications and technical drawings to building prototypes and performing a range of product tests in our high-performance testing laboratory. That’s how we make sure your customised products are professionally manufactured to satisfy the most stringent quality requirements: in terms not only of technology but also of cost efficiency and security of investment.

BRUGG eConnect has built up a valuable store of experience over the years through working with many different industries.

Requirements in terms of quality of individual components in a cable connection can vary greatly. After all, special cable connections are used only when standard commercial products are unable to meet the necessary requirements.

That’s why we develop cables for you that combine properties such as hydrolysis, microbe, UV and ozone resistance, electromagnetic compatibility and 100% outdoor functionality, while also offering a high level of flexural fatigue strength. A special or hybrid cable can be designed for different voltages simultaneously, and consequently contain wires with different cross-sections.

This broad range of tasks means we have to be highly flexible in terms of our processes and very reliable in implementing orders. Whatever your task, talk to our specialists about your needs.

Product features

-

Specialist for flexible cables

Cables adapted to your application. -

Customised hybrid cables

We combine energy, signals, data, air and water in one cable. -

Engineered-to-order

We consult, develop, produce, test and assemble your cable solution (plug and play).

Tailor-made cable connections from BRUGG eConnect come into their own when quality is demanded. Thanks to more than 100 years of experience and countless successful projects completed for the industry. And thanks to a broad product range and innovative solutions.

Whether it’s for the army, the mechanical engineering industry, security firms, or rail and road transport, the industry makes major demands on cable systems in terms of reliability and robustness. From our experience to our products and entire systems, we offer solutions to suit your needs. We specialise in evaluating customised cable connections, including the associated plug connections, and monitoring the process through to series manufacture.

Cable assemblies

engineered-to-order

Product features

-

Our advantage for you

Cables adapted to your application. -

Complete cable solution (cable and assembly)

We consult, develop, produce and test your cable assembly.

Special requirements call for special solutions. That’s why we are the preferred partner for customer-specific cable assembly, and an impressive number of additional services besides.

Cable cutting and stripping machines, crimping units and modular manufacturing facilities – for more than 20 years we have been providing reliable services in cable assembly and injection-moulding around inserts, plugs and screw connections.

Not only do we use all quality standard fibre-optic and copper plug connectors in hybrid cable solutions for indoor and outdoor use, but we also work in conjunction with leading suppliers around the world. That means we can provide the desired cable assemblies at any time, thanks in part to our state-of-the-art machine fleet, optimised processes and the vast expertise our specialists have built up.

We are here for you!

Your sales consultants:

|

Johannes KnollM +41 56 460 38 39 |

| Alberto Nebel |